|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Willen Employment

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Basket making

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wicker baskets must have been made in Willen for hundreds of years, because the village gets its name from the willow trees that grow along the banks of the River Ouzel. Willow wands can be woven into a great variety of shaped baskets that were used for almost every purpose until plastic became available. In 1881 only Amelia Goodman was a basketmaker, in the village.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Seed lip, used for carrying seed during hand sowing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

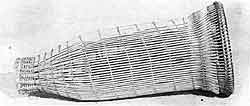

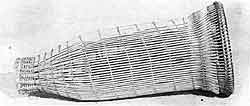

Eel basket, this would often be placed in a watermill's millrace and would trap eels as they passed through. |

|

|

|

|

When willow trees are not harmed by regular cutting. If they are cut back to the ground they readily sprout up and produce many long thin very bendy shoots. These wands or 'withies' are cut at ground level and dried and bundled ready for basket making. Next year new wands will grow up from the old willow stool.

Withies can be used with or without the thin bark, depending on the desired appearance of the finished article. When the basketmaker needs withies to make a basket, she must first soak the withies to make them soft enough to bend easily. The withies must be worked in damp conditions. |

|

|

|

|

|

|

|

|

|

|

|

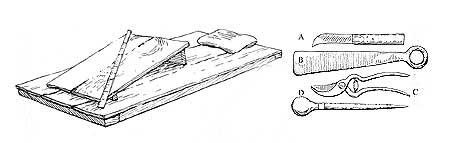

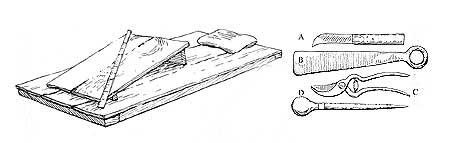

Left: the basket makers plank and lapboard. Right: the essential tools, A, shop knife; B, beating iron; C, shears; D, bodkin. |

|

|

|

|

|

The basketmaker sits on a plank, (a board around 1.7 metres long and 80 cm wide) with the withies on one side, the few tools needed on the other, and with their slightly sloping lap board in front of them.

The essential tools were few in number and cheap: a sharp curved shop knife, shears, a beating iron for knocking down the weaving, and a steel bodkin for piercing holes. All Amelia would have needed was a room where she could sit on the floor with her back to the wall which was big enough to move the withies around. |

|