|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

How to make a brick at Stewartby

|

|

|

|

|

Clay is cut from Lower Oxford clay by mechanical navvy

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clay is placed in crushing machine at the pit

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clay travels along conveyor belt to works

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Crushed clay loaded onto conveyer belt for journey to works

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clay is crushed several times to remove impurities

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clay is mixed and tested to ensure uniformity of product

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Common Flettons are left plain but patterned bricks are damped and have special finish added |

|

|

|

|

Clay placed in brickmoulds and double pressed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

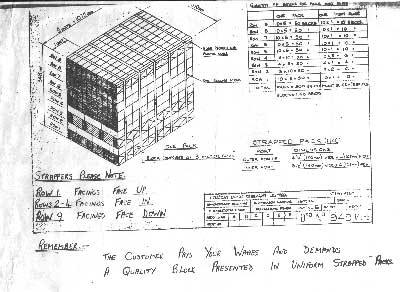

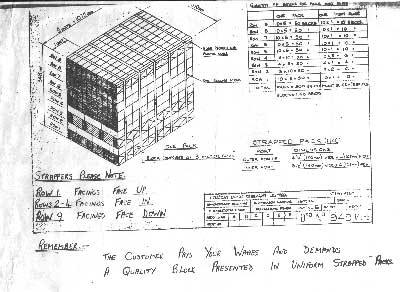

Bricks sent along conveyor built to be stacked by hand

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brick stacks taken to kiln by forklift truck

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bricks are allowed to dry then sealed into kiln for start of 11 days firing cycle

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fired bricks are removed by fork-lift trucks to stacking sheds

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bricks are checked by hand and strapped ready for sale.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|